Surface characterisation

Why surface analysis ?

During elaboration or use of a material or a new product, surfaces often play a major role.

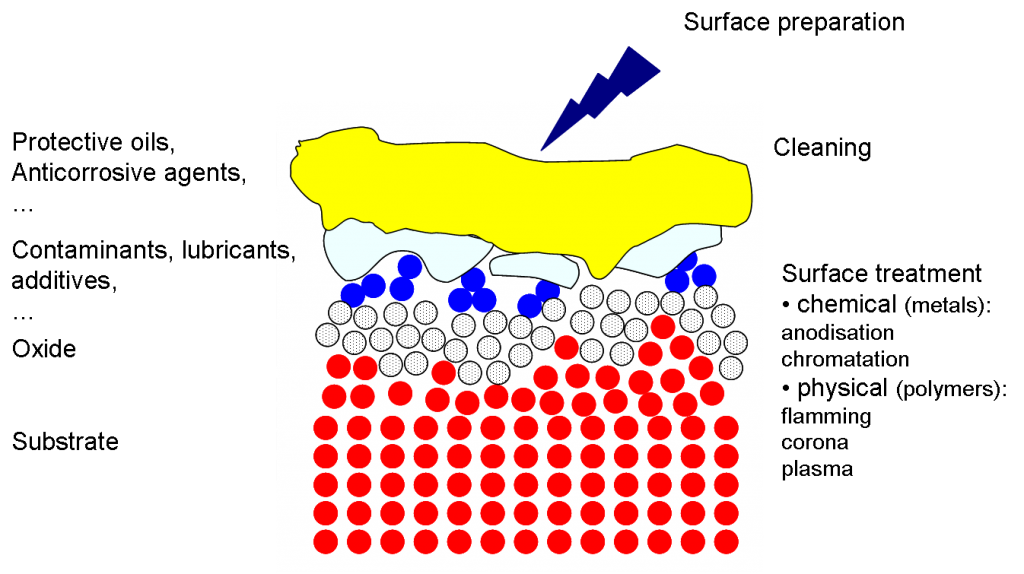

Wear, corrosion, adhesion… arise from the physical and chemical properties of the surfaces and interfaces. So, they need to be characterised in order to well understand the interactions occurring.

In many fields, surface analysis techniques help to control and improve material performances, thus leading to an increase in competitiveness.

- In Research and Development, surface analysis techniques are a knowledge tool, and help during process optimisation.

- In Production, surface analysis techniques can become a real tool to check quality and reproductibility of surface states.

- For Problem solving (weldability, adhesion, contamination…), surface analysis techniques are also powerful means of investigation.

For which information ?

Surface analysis can give information on:

- Elementary and quantitative analysis of the top atomic layers: from nanometer to a few tenths of micrometers,

- Chemical analysis: information about bonds, oxidation states, functional groups,

- Molecular analysis,

- Trace analysis,

- Elements localisation with a high resolution:

- In depth: profiling (from a few nm to a few μm),

- Spatial: elemental and molecular imaging (resolution <1 μm),

- Any solid material analysis, including powders and insulating samples.

These various aspects can be covered y our own and complementary facilities (available through selected partnerships).